April 12, 2025: Double trouble with an 18" set

All text and images copyright Michael E. Lockwood, all rights reserved unless otherwise noted.

When I receive optics for

testing, I usually don't have much of an idea of what I'm going to

find. It can be anything from an excellent mirror to one needing

slight tweaking, to one that needs a complete re-polishing to remove a

nasty rolled edge, and occasionally one that is not completely polished

out and might even need some grinding. This is why I can't quote

refiguring costs until I test, and why I do refiguring by the hour to

keep it fair for client and optician.

When I receive optics for

testing, I usually don't have much of an idea of what I'm going to

find. It can be anything from an excellent mirror to one needing

slight tweaking, to one that needs a complete re-polishing to remove a

nasty rolled edge, and occasionally one that is not completely polished

out and might even need some grinding. This is why I can't quote

refiguring costs until I test, and why I do refiguring by the hour to

keep it fair for client and optician.In this case, the client had an 18" set that he didn't think was performing as well as it should, and when I heard the name of the source of the optics, I knew the mirror might have some issues. It was an older manufacturer from decades ago that had put out some real crap, and I remembered that I had fixed one long ago in the infancy of my optical career. As I recall, it barely had any correction.

However, this primary did, and it was not that bad of a mirror in terms of shape. Of concern, though, was how the primary mirror looked under Foucault testing. It was odd. There were apparently large pits in the substrate in the shape of the arcs traveled by the diamonds in the diamond generating tool. There were some other strange features, too.

See the image to the right - notice the layered appearance in some areas and bright spots (pits). It was clear that this mirror had not been fully ground originally, and therefore polishing had been unable to fully polish out the pits. I had suspicions about what was going on, so I took a closer look.

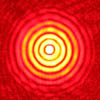

Upon inspection of the pits with a microscope and bright illumination from the side, I noticed small fractures in the surface of the mirror. I immediately realized that this was a sign of chemical damage, likely from caustics used to remove coatings. Finally things made sense.

If a caustic (or other chemical) is too strong or is left on too long, they can damage the top layer of glass, and will eat into tiny fractures such as those left behind by insufficient grinding and/or polishing. That's what had happened here, I believe.

I was able to get some decent photos of the fractures with my small Canon G15 camera in various places, but the lighting was best near the edge of the mirror, where, coincidentally, most of the pits were, as can be seen in the photo above. The fractures are seen in the photo below on the left. The edge bevel of the mirror is seen running nearly vertically through the center of the photo. The mirror's surface is to the left of that where the fractures are seen.

What this meant was that the mirror needed to be completely reground, polished, and figured. I informed the client that my original estimate was going to go higher due to this unfortunate find, and he understood.

To add insult to injury, the 3.5" m.a. flat proved to be around a wave from flat, and it was replaced with a new one. The mirror ended up with a superb figure, and I'm looking forward to some observing reports from this optical set after everything is coated.

Please check back for future installments of "In the Shop".

Mike Lockwood

Lockwood Custom Optics