April 24, 2018: Interferometry is only a piece of the puzzle

All text and images copyright Michael E. Lockwood, all rights reserved, unless otherwise noted.

In my shop, we embrace interferometry for what it is good for - showing asymmetric errors, revealing interesting phenomena, and giving false hope to those who don't use other tests.

I was having a good day, and a mirror had just come in for testing. The phase-shifting interferometer was already on, set up, and warmed up, so it was ready to measure the 12.5" f/6 that had just arrived and had equilibrated to shop temperature.

(Going off on a tangent): If you're a Big Bang Theory fan, you might recall Leonard saying that the first thing he turned on when he came into the lab in the morning was the helium-neon (He-Ne) laser, because it needed to warm up. This is true for interferometers, too, because the professional models use such a laser. If you try to measure before the laser has warmed up and its dimensions have stabilized, you will be measuring moving fringes and the result will be erroneous. The housing of the laser has to stabilize in temperature so that its length stabilizes and the laser output itself is stable. (/tangent.)

So, with that wonderful HeNe laser all warmed up and calling out to be used for measurements, I stripped the coating off the 12.5" f/6. I set it up on a stand and took a measurement. I was surprised to see minimal astigmatism. I measured the radius of curvature, calculated the amount of spherical aberration to remove for an artificial null, and it was almost identical to the amount of measured spherical aberration.

These were good signs, I thought.

Maybe this one will be as good as it appears to be.

Here is the result of the interferometry. Astigmatism is small, and aside from some roll off at the edge, which is often due to the analysis, it looks pretty darned good. Of course there are some fringe artifacts, but this is normal, and in this case I could not get rid of them.

I saved the data, shut down the interferometer, and moved it and the associated electronics out of the way.

The Foucault tester, costing a tiny fraction of the interferometer's cost, was set up in its place, shades were drawn to keep out the sunlight of a beautiful day, and, with great anticipation, I had a look.

Oh crap. This is not good.

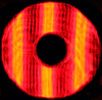

Immediately visible on the mirror, with the coating stripped, are a variety of sleeks, gouges, and what appeared to be a fairly nasty rolled edge. The light edge on the left and the dark on the right in the image above indicates the rolled edge, which was actually fairly broad. The circular feature about 1/3 the diameter of the mirror is a reflection off the glossy back surface of the mirror, which is one reason why I prefer to grind the back surface.

I set up the camera and recorded the image above, and that below - another Foucault image with the knife edge moved farther from the mirror to null zones closer to the edge of the mirror.

Now we really see the rolled edge as bright on the left and dark on the right. The surface looks just as nasty as before.

Given the appearance of the Foucault test, the optical surface itself, in terms of polish, was probably not in good shape. I did take some readings of correction, as best I could, to check that the correction was close like the interferometry suggested, and I saw good agreement, except in the outer zone which was not easily read accurately due to the rolloff.

The last test (after a fairly good strain test) is to examine the polish of the surface.

Oh damn. This is not good.

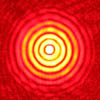

What we see above

is a bright light source shining on the mirror's uncoated surface. The area with all

of the specs is where the beam of light is hitting the

surface. For

a perfect polish, nothing should be seen, but in this case it looks

like Omega Centauri or another bright globular cluster, and each

"star" in the cluster is a pit in the optical surface. There

were

also a significant number of scratches, some bad enough to show up with

Foucault.

What we see above

is a bright light source shining on the mirror's uncoated surface. The area with all

of the specs is where the beam of light is hitting the

surface. For

a perfect polish, nothing should be seen, but in this case it looks

like Omega Centauri or another bright globular cluster, and each

"star" in the cluster is a pit in the optical surface. There

were

also a significant number of scratches, some bad enough to show up with

Foucault.Thus, the conclusion is that, unfortunately, this mirror needs to be re-ground, polished, and figured all over again.

It appeared that a chunk of glass had been forcibly removed from its back of the secondary (flat) mirror by pulling it off of some aggressive adhesive! By that, I mean that it was glued to something, and someone just tried to pull or pry it off instead of cutting the adhesive, and part of the mirror was left behind. (If anyone ever asks if you trust silicone glue holding an optic, remember this story.). If the "flat" was once good, it surely was not now. See the image at right - the fringes should be straight, but they are far from that, and the pattern is chaotic. It had well over one wave of error, and it is now best placed in a trash can.

Thankfully, in this case, the owner of the optics hadn't paid too much for them, and he was not that heartbroken when I called him and told him the bad news about his glass. He has decided on a much thinner, new 12.5" from a superb manufacturer, and I forsee him having many enjoyable nights with his new set of optics.

You win some, you lose some.

Please check back for future installments of "In the Shop".

Mike Lockwood

Lockwood Custom Optics