December 18,

2013: A

half-baked secondary mirror

All text and images Copyright Michael E. Lockwood, all rights

reserved.

I picked up some optics on the way home from a trip - a 32" mirror for

testing, and the 6.25" m.a. Pyrex flat that goes with it. The

flat was

glued to a piece of aluminum.

First, let me say this - unless you know EXACTLY what you are doing, I

never recommend gluing a high-quality telescope mirror to anything.

Smaller secondary mirrors are the only exception, say under

3"

m.a., but there is still a chance of astigmatism as the glass and

whatever it is glued to cool and change dimension at different rates.

Note: The best thing to glue a piece of glass to is another

piece

of glass. That piece can then be bolted carefully to

something

else. The second piece of glass will expand underneath the

bolts,

allowing the change of dimension, and preventing the mirror from being

significantly distorted.

Normally freeing the mirror from glue is no big deal - you simply slide

a

piece of wire, a razor blade, or a putty knife under the

mirror,

cutting the adhesive. However - this assumes there is space

between the mirror and what it is glued to.

In this case, there was no space! Clearly the genius that did

this did not anticipate ever having to remove the mirror. So

what

to do?

After some consultation, it appeared that most adhesives would lose

their strengths above ~400 degrees F. So, into the oven the

Pyrex flat

went, slowly ramped up to 425 degrees F. I left it there for

a

few hours, and found that at some point the flat had slid down its

holder by ~1/2", as can be seen in the image below. I figured

the

glue was done for, and cooled it off slowly.

(Disclaimer - I take no responsibility if you try this and something

goes wrong. You certainly don't want to do it with a mirror

that

is made from something other than Pyrex or another lower expansion

substrate like quartz, etc. Anything you try is done at your

own

risk.)

However,

upon

removal of the cooled-off items, attempts to separate the mirror from

the metal were

unsuccessful. The glue was still holding, and there was still

no

gap between glass and metal. So, at this point the flat was

literally only half-baked!

After another thermal cycle the next day and some gentle persuasion

with a putty knife, the mirror finally separated from the metal and it

fell away, as can be seen above. A razor blade is just

visible

wedged between glass and metal at left.

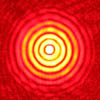

After cooling, I set the flat up for interferometric testing in my 24"

collimated beam. The results below show a flat that is

decent, but it

can likely benefit from some tweaking and can be improved further.

It

certainly merits some more testing after the coating is removed.

Please check back for future installments of "In

the Shop".

Mike

Lockwood

Lockwood Custom Optics