November 22,

2013: Not made in the USA All text and images Copyright Michael E. Lockwood, all rights reserved.

I wanted to write this installment as a warning to some.

People would like to buy a cheap telescope, have the mirrors checked

and/or refigured, and then have an optically excellent telescope for

not too much money.

Unfortunately, it appears more and more that the buyer is rolling the dice.

In the past, import telescopes used Pyrex glass. Even though it

was cheap Pyrex, the glass was of decent quality, typically with mild

strain, not severe. Pyrex is more stable during temperature

changes than less expensive plate glass and BK7 glasses, for example.

(Quartz is six times more stable than Pyrex because it expands by

1/6 as much as Pyrex for a given temperature change.)

However, cheaper glasses are now being used in these telescopes, and I

have seen a decline in the quality of the annealing, if they were

annealed at all.

Below are Foucault test and strain test images of a 12" primary mirror that

a client sent me for testing and possible refiguring. There is

also an interferogram for the secondary mirror (flat).

The figure was fairly good, but there is significant roughness on the

surface of the mirror, as seen in the photo of the Foucault test above.

The above image shows the strain test for the blank, showing a lot of

strain near the edges, and quite a bit through the central areas too.

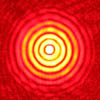

The flat that came with this optical set was clearly not flat, and in

fact shows about 1/2-wave convex. I fixed the flat, then turned

my attention to the primary.

I found the glass very soft, and the primary mirror figure was slowly

changing over time. Therefore I declared it unsuitable for my

work.

The moral of the story is that if you buy a cheap telescope, you are

rolling the dice, and may not get optics that can be improved by

refiguring.

Here's a bit more of an explanation - if there is internal stress in the glass, the mirror might change shape over time.

To anneal glass, it is heated to the annealing temperature (1040 deg F for Pyrex) and then slowly cooled.

During this process, the strain causes the glass to change shape, and this relieves the stress.

So, after annealing, the mirror is no longer a mirror - it must be re-ground, polished, and figured all over again.

Thus, a mirror with severe strain is only worth the raw glass that it

is made from. To keep prices down, one can use cheap,

poorly-annealed or even un-annealed glass and claim it is

annealed. The only way to check is to strip the coating and check

with polarized light, and most people are not going to do this.

Even fewer are going to pay to have the mirror annealed and completely

re-worked.

Now let's say a less-expensive glass, say for example BK7 is used -

this glass has a CTE (coefficient of thermal expansion) that is about

twice as much as Pyrex, so it's going to change shape more while it

cools. It is also softer, and more prone to become rough during

aggressive polishing and figuring.

For telescope mirrors the "you get what you pay for" rule certainly applies.

The client decided on a replacement mirror, a 13" f/4.6, 1.1" thick, Pyrex mirror (made from a blank with excellent anneal).

If you don't want your optical quality to be determined by the roll of

some Asian dice, I have some 13" f/5 blanks, 14.5" f/4 blanks, and 16"

blanks (and larger, of course). I'd be happy to make you a

high-quality primary mirror for your telescope structure from any of

these.

For other sizes or custom focal ratios in mirrors under 16", Carl

Zambuto would be happy to make you a high-quality primary mirror, and

to coat it himself. Congratulations on getting your coater

running superbly, Carl.

Please check back for future installments of "In

the Shop".

Mike

Lockwood

Lockwood Custom Optics