July 10,

2012: Big Blue gets a new 36" f/6.3 mirror

Last year the 31" f/7 primary of "Big Blue", the telescope housed in the

Warren-Rupp Observatory near Mansfield, OH, was tragically broken when

the secondary mirror and holder came loose from the spider and

struck the primary mirror. The collision didn't do that much to the secondary, but it cleaved the primary in half.

I

got a surprisingly calm call from a club official on the same

night asking if it was possible to make a replacement. After finding my 50' tape measure, and

measuring the length of the test path that I could manage diagonally

across the main shop space to see if I could test such a long focal length mirror,

I saw that I had enough room and said

yes.

With

a ~450" radius of curvature, I needed nearly a path 38

feet long to set up the test! As a fallback, a known good flat

could have been used to fold the optical path, but I wanted to avoid

that.

Two quotes, one insurance claim (fortunately the mirror was insured),

and some creative thinking

later, a plan was born to NOT replace the mirror with an exact replacement, but instead to greatly

improve the telescope.

A larger 36" f/6.3 primary could fit in

the oversized tube, and it would be thinner and thus cool faster than

the old primary. A new mirror cell would be needed, and would update the mirror

support to modern standards. A rotating secondary mirror holder

that can't possibly come loose

and a second focuser would allow the telescope to be used over a much

larger area of the sky.

So, instead of a tragedy, this became a serious upgrade.

Some

might observe that I normally make f/3.6 mirrors, rather than f/6.3,

and this is true, though I always enjoy a change of pace like this

"slow" mirror. The glass arrived some months ago, and I have now

completed work on the primary mirror. Some photos are included

below

to show the progress.

Below, the back of the 36" mirror is ground

against the back of another smaller mirror, a 22". (For more on why

the back should be ground, see this installment

of In the Shop.) The mirror just fits on my medium-sized machine,

which has a 34" turntable. So, the mirror overhangs about 1", but

this is not a problem for such a thick mirror, and actually helps with

cleanup.

Next,

a hydrostone (water resistant plaster) grinding tool is cast against

the mirror, and after it dries, tiles are epoxied to its face to

complete the tool (image below). A socket is attached to the back

to accept he pin from the machine's arm. This type of tool can

be made quickly and affordably, and is ideal for radii that are not

likely to be used very often. (A ~225" focal length mirror is not

a common thing in my shop.)

The

grinding tool is then used to grind the face of the mirror from fairly coarse grits down to very fine

grits so that it is then ready for polishing. Below is

a photo of early grinding work to break the tool in and get it into

good contact with the mirror. After this, the arm position is

varied to control the curvature of the mirror. A spherometer is

used to measure the curve, and adjustments are made during various stages of grinding to bring the focal

length to the desired value of 224"-225".

Finally,

after grinding down to 5 micron abrasive, grinding is finished, and

the low-angle reflection of the mirror can be admired and photographed. It is always a beautiful thing to behold.

A scratch-free grind is a major milestone for a large project.

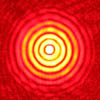

The mirror was then polished for many hours until any traces of

grinding pits were removed. After polish was complete, the figure

of revolution looked good, so it was then "figured", or polished to the

proper parabolic shape.

Figuring

was completed on July 9, following careful testing. The figure of

revolution was checked a last time, dried cerium oxide was removed from the edge of the mirror, the

bevel was touched up, and several small circles were scribed in

the glass in the exact center of the mirror to make it far easier to collimate.

Most of my clients really like this feature, because it allows

collimation stickers to be precisely centered, and the direct reading

of laser collimators.

Here's a photo of a somewhat tired

optician, happy that the project is completed slightly ahead of

schedule, and trying to smile as he takes a photo of himself.

The little sign says: 36" f/6.3 - COMPLETE.

After

final inspection of the surface, it is covered with acid-free paper and

a piece of cardboard to protect it, and the primary mirror and new

secondary mirror are packed in a crate for shipment to the coater.

The coated mirror will then be tested in its new mirror cell (inside

the shop) to make sure the edge support is working properly.

If all goes according to plan, the mirror will be reinstalled in "Big Blue" and the other upgrades done before Hidden Hollow 2012, a yearly star party that features the telescope, which I may start calling "Bigger Blue".

Please check back for future installements of "In

the Shop".

Mike

Lockwood

Lockwood Custom Optics