April 7,

2012: An 18" in rough shape, literally

Some

mirrors test out very well when interferometers are used, because

interferometers don't show small-scale roughness, and in some cases,

large scale roughness of small amplitudes.

Don't get me wrong -

interferometry is an incredibly valuable too for, say, checking the

figure of revolution of a large mirror after polishing or during figuring, looking for

test stand distortion in a test setup, or testing a system of optics in

combination with an autocollimation flat. The interferometer

yields a 3-D representation of the wavefront error of the

mirror/system, which shows the problems quite clearly over all parts of the system.

It does not, however, show certain things that make a real difference in the performance of a telescope.

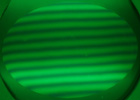

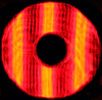

This

mirror came in for refigure from a client who was not overly

enthusiastic about its performance. The surface is clearly rough,

especially near the edge of the mirror, in the Foucault photos below.

Ignore the water marks, insect tracks, and dust. Look at

the

underlying texture of faint lines on the optical surface. It

almost looks as though the entire surface has been sanded with

sandpaper.

Also

note the lack of a bright diffraction ring around the outside of the

mirror on the right side. This indicates that the edge is rolled.

A faint "groove" is visible about an inch inside the outside edge

of the mirror, which is clearly the result of some aggressive figuring

to "knock down" the outer part of the mirror in order to get better

test results for the larger-scale figure of the mirror.

The

mirror, in this condition, will produce images in which light is

scattered around bright point sources. This will bloat stars (due

to roughness and some errors in the overall shape) and decrease

contrast on objects like planets.

For this mirror, my job was to tune the figure and

smooth the surface as much as practical, keeping costs within reason,

while trying to improve the rolled edge in a manner that didn't break the bank. This was not a very

broad rolled edge, maybe 1/8"-1/4" wide, far from the widest I have seen, but at the edge it was quite a sharp drop-off.

A

complete polish back to a sphere would be two to three times as

expensive as some careful figuring work along with beveling away the

worst of the rolled edge with a diamond

hone.

The

mirror was smoothed, the figure tuned, and the bevel was increased to

erase most of the rolled-edge nastiness. To completely eliminate

all traces of it would have more than doubled the cost of the

refiguring work, and the client and I agreed that this did not make

sense. The mirror had been greatly improved over its previous

condition, had a very good figure, and that was sufficient. As I

do with most mirrors, I also added some precisely-centered circles

scribed into the optical surface to mark the center of the mirror.

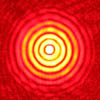

Below

are

the after refiguring photos, showing the much smoother optical surface.

The same processing was done on these photos as the ones above,

and no smoothing of the images was done.

There are a few smudges of dirt and residue near the bottom and a

few spots on the surface. None of these are defects in the

polished surface.

While

a small part of the original edge roll remains, it is now narrow enough that it will likely not make

a difference in images. The client can always mask it off if he

is annoyed by it, which is far cheaper (2x to 3x cheaper) than polishing it away and then

doing even more refiguring from a near-sphere.

In

the case of a refigure, the cost of absolute perfection sometimes

doesn't make financial sense. However, if I am figuring a mirror

from a sphere, the only reason to use the types of techniques that

cause nasty edge rolls, in my opinion, is if you are in too much of a

hurry to care.

Please check back for future installements of "In

the Shop".

Mike

Lockwood

Lockwood Custom Optics