November 25,

2011: Not up to my standards - 16", Part 1

Well, this example shows quite nicely what a mediocre mirror is.

The

client complained of..... well, he didn't complain, but he said the

mirror was merely "OK". He wanted a better idea of what was going

on.

First I tested the elliptical flat, which turned out to be quite good.

Next

came the primary. Foucault testing showed a good amount of

roughness on the optical surface, as shown in the images below.

Also seen is a slight zone near the center of the mirror, but

likely behind the secondary's shadow.

The "roughness" is seen in

the shadows - they look blotchy, and "not smooth" in general. The

mirror appears to have "texture" over most of its surface, and this is

the roughness. It may reduce the image contrast in critical

observing, and also can affect test results when high precicion is

desired. Roughness is observed over most of the optical surface,

and was likely caused by a heavy-handed optician, working in a hurry

with a hard pitch lap. Edge condition was OK, but not perfect,

with a brighter diffraction ring on one side of the mirror than the

other, though this is quite a minor defect even for a very good mirror.

The figure and roughness are of much greater concern.

Further

testing showed the mirror to have a very good figure of revolution, but

the figure was at best 1/4-wave on the glass, or 1/2-wave on the

wavefront. I know from experience that this is far too much error

to be caused by the surface roughness affecting the Foucault readings.

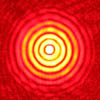

The

error plot below shows the error in the figure, as measured with

Foucault testing. It generally looks like overcorrection.

Also note the transverse error of 4.16 (slope error relative to

the airy disk size), which indicates stars will definitely not be at

their sharpest.

Obviously,

refiguring and smoothing work is recommended, to which the client

agreed. It will be done when I can work it into my schedule.

Please check back for future installements of "In

the Shop".

Mike

Lockwood

Lockwood Custom Optics