April 1,

2011: Unfortunately

NOT an April Fool's Joke

The old adage goes - "You get what you pay for." In this

case, the client found it out the hard way.

He

bought a piece of "quartz" from a Chinese glass company. Keep

in

mind that at this point, Chinese glass is not exactly the greatest in

quality. The blank didn't look too bad after we generated it,

so

I agreed to proceed and see how it ground and polished.

Immediately

into grind I noticed parts of the glass contained signifant impurities

and bubbles. Clearly, it was not going to be up to the

client's

standards when polished, and I let him know. I also said I

would

continue and polish it out, to see how the surface looked.

Then,

hopefully it would be useful for an application where lots of bubbles

didn't really matter, such as LIDAR, etc.

Here's what it looked

like as it was being polished. At this point all of the

"stuff"

in the glass could be seen, and where they met the surface some marks

could be seen. Still, I felt it might be optically useful,

and I

kept the polishing machine spinning.

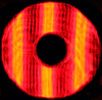

After

putting a good polish on it, it was time to put another mirror on that

machine, and I decided to give the mirror a quick Foucault test.

Here

are photos of the test - the first photo is at 0.000", the

second

photo is 0.025" farther away, and the third photo is 0.025" farther

away.

The

rotation of the knife edge shadow is clear and dramatic, an indicator

of severe figure of revolution problems. In fact, I have not

seen

a figure this asymmetric since I tested Bob Holmes' 32" mirror after it

was returned from an incompetent optician. (See these images of 32" mirror before

I reworked it, and note the asymmetry of the shadows.)

Also

note the "fingerprints" of the "features" in the glass where they

intersect with the surface. These form dark and light areas

across the surface.

In this case, the substrate is at fault.

No material should polish out with this much astigmatism.

It's simply BAD GLASS.

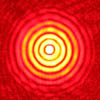

To add a quantitative aspect to the measurement, I set up my

interferometer and snapped a photo of the image on the monitor.

The

fringes clearly show a "saddle" shape, where two quadrants on one axis

are higher than two quadrants that lie on an axis perpendicular to the

first. In other words, using a clock face as a reference, the

mirror at 10:30 and 4:30 is either higher or lower than the mirror at

1:30 and 7:30.

To quantify the error, simply count the fringes

between neighboring quadrants. My count gives 15 - 16

fringes, or

7.5 - 8 waves on the glass.

So,

this piece of glass is not very useful. Not sure what we'll

do

with it. Maybe it would make a good bird bath, or possibly a

table top.

So what is the moral of the story? Certain

sources of glass are not to be trusted, and you should trust your

optician to select a good supplier to provide the substrate for your

next telescope project. Life is short, but you can be stuck

with

a bad mirror for a long time if your money is not spent wisely.

My

sources for glass have a track record of good annealing, good

machining, and timely delivery. That's why I have chosen them.

Please check back for future installements of "In

the Shop".

Mike

Lockwood

Lockwood Custom Optics